Volume 14, Issue 2: Dangers of Oil Filled Gear

System Improvements - Dangers of Oil filled gear

Over the past few years, Utilities have faced intense scrutiny and criticism over steps they are taking to improve system hardening and the actions that can help prevent fire events from occurring on their systems. There have been several products introduced which can help lower the risk of wildfires throughout power systems including surge arrestors, cutouts & fuses that minimize fire producing sparks, covered line wire, pole coatings & wraps, and grid monitoring.

An additional area of concern to utilities that may not get as much attention when it comes to fire mitigation is oil filled gear. Operational reliability is vital when it comes to any switchgear or under oil fused gear. With the ebbs and flows of our climate in the mountain region, oil filled gear can be especially prone to failures and faults. Many times, these failures stem from contaminated insulating oil and moisture ingress into oil chambers due to drastic temperature swings. With maintenance procedures being so meticulous on oil filled gear, this can cause longer than necessary outage periods for our members. Over time, catastrophic failures are also an unfortunate reality with oil field gear. With safety being a primary concern for our member utilities, newer and safer technology should be considered when replacing oil filled gear on your system.

Please reach out to your Western United sales representative for suitable alternatives to any of your old oil filled gear as well as any other fire mitigation related products and solutions.

Employee Spotlight

Meet Eric Royer

Eric first joined WUE in 2001 working as a warehousemen and delivery driver for the better part of 8 years. He left WUE in 2009 to accept a job as a process instructor for Vestas for a few years, followed by a stint in the oil field as a construction manager and finally, working as a parts and inventory manager for a fire truck sales and service company. As soon as Eric got word that a position in sales opened up at WUE, he jumped at the opportunity. Eric rejoined WUE in 2018 as an inside sales associate and has recently earned the title of senior inside sales representative with Western United. Eric’s wife Jessica also joined WUE in 2019 as a purchasing assistant. Between them, they each have 3 children of their own (6 total like the Brady Bunch). Eric is especially proud of his oldest daughter who is serving in the US Navy and has recently been stationed in Pensacola, FL. Outside of work Eric enjoys playing guitar, disc golf, and camping. Eric’s WUE roots run deep and we are fortunate he re-joined the WUE team!

Western United’s 45th Annual Meeting

Western United’s 45th annual meeting was held March 9th during the CREA winter meeting. This year’s meeting was held as a virtual online meeting. If you were unable to attend, a full report is available on our website at

Featured Manufacturer

Featured Product

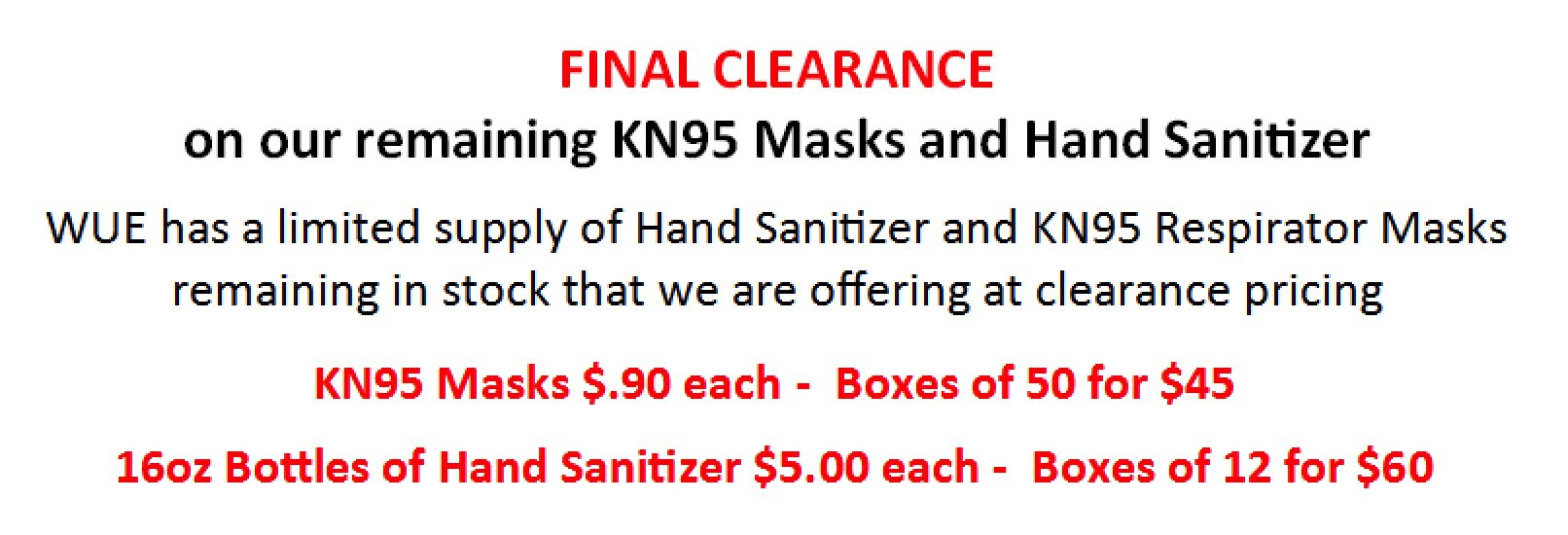

Quantities are limited so contact your WUE Account Representative today for more details