Volume 13, Issue 4: Product Lead Times

Product Lead Times Reaching Unprecedented Levels

Pad Mount Transformers, Underground Cable, and Fiberglass Enclosures make up the backbone of the underground infrastructure of our utility systems. Market conditions are creating a perfect storm affecting the lead times of these key products. Over the last six months, our key suppliers have seen a dramatic increase in the volume and size of new orders. This increase is due to the continued surge in new housing that has been seen in all geographic regions. This surge in new orders has rapidly increased the lead times on these key products and manufacturers are trying to keep up with this increase in orders. Added to the increase in demand is the COVID virus, which has affected all manufacturers to some degree. Manufacturers have redesigned their production workflow to add time for cleaning and have created spacing be-tween workers to meet distancing requirements. They have also experienced employee absences due to COVID infections. They have also experienced the same longer lead-times from their suppliers as they battle the same issues. In the last six months, Western United has seen lead-times go from a consistent 4 – 6 weeks to 6 – 9 months on some products. We have seen some manufacturers close plants in Mexico and China due to these countries shutting down businesses they deem non-essential to slow the spread of COVID 19.

Holiday Schedule

Western United Offices will be Closed

November 26th & 27th for the Thanksgiving Holiday

December 24th & 25th for the Christmas Holiday

Friday January 1st for the New Years Holiday

Employee Spotlight

Meet Chris Bennett

Chris Bennett joined the Western United team in January of 2018 as our Director of Purchasing. He is the person responsible for spending millions of dollars each year to ensure WUE has the products your utility needs. Chris has had a diverse career including 9 years in wholesale distribution with National Wood Products where he managed their purchasing department as well as 15 years in the restaurant business and 6 years as an assistant golf pro. Chris is a Colorado native and has been married to his wife Kacey for 18 years. They have a daughter, Ireland, which also tells you his favorite travel destination. When not diligently working for WUE, you can find Chris on the golf course or smoking a brisket in his back yard. Over the past 3 years, Chris has developed positive and productive relationships with WUE’s suppliers and vendors. He is a welcome asset to our team.

Featured Product

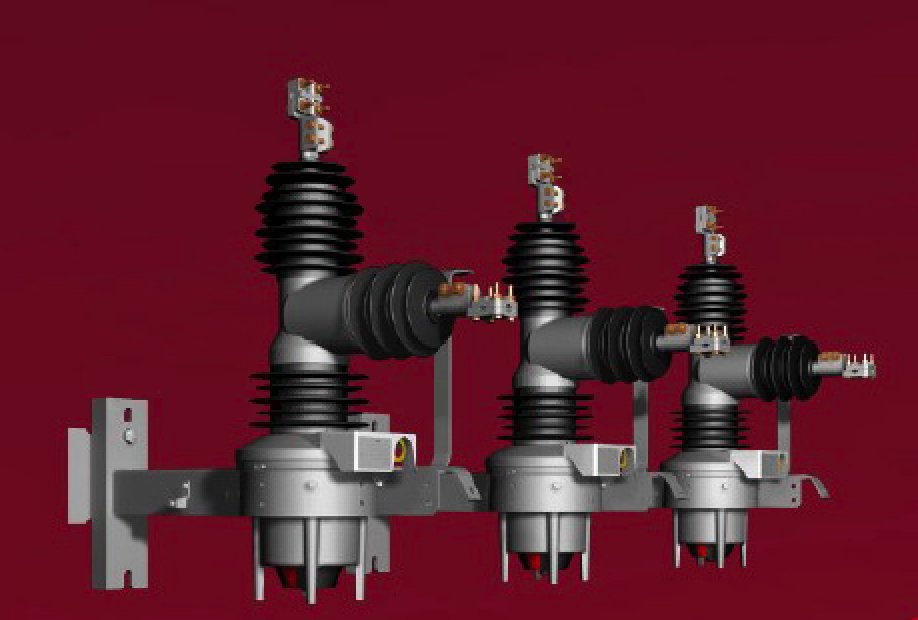

For more than 50 years, utility companies have relied on the Elastimold ™ brand for products to support grid investment projects and day-to-day installations. The Elastimold recloser can be adapted to meet your specific needs in applications from 15 to 38 kV. It is assembled in Hackettstown, NJ, USA, where ABB continues to invest in manufacturing to improve product lead times. Learn more at electrification.us.abb.com.

WUE stocks ABB Elastimold reclosers

Light weight

800A ,150BIL isElastimoldsstandard

Best in class creepage

1ph & 3 Ph tripping capabilities

10,000 trip and close full load operations with no maintenance required

Easy to see position indicators

Comes with SEL controls.

Available in 15KV, 27KV and 38KV

Made in the USA

Hendrix Tap Wire

Designed for better reliability and wildlife protection

Hendrix tap wire is a stranded or solid copper conductor covered with a 0.150” layer of flexible, black, thermoplastic elastomer. It provides a covered lead from primary phase conductors to equipment bushings.

Greater reliability. Utilities are using Hendrix covered tap wire for jumpers and connections on most bare wire applications to improve the reliability of the circuit.

Wildlife protection. Using covered tap wire avoids outages due to wildlife contact with the energized tap and another phase or a ground plane, such as a transformer case.

Durability. Hendrix tap wire has excellent ultraviolet and weathering characteristics, which maintain covering integrity. The tap wire’s thermoplastic elastomer covering is more flexible and trains more easily than polyethylene covering.

Key Features

Higher Voltage breakdown strength, ideal for 15-35kV applications

Hendrix Tap Wire will reduce or eliminate outages due to wildlife contact

Rubber-based covering for easy stripping

Bends with memory (no flex-back)

150 mil covering, the thickest in the industry

Suitable for all open wire systems, including bare wire, weatherproof, tree wire, and Spacer Cable